Which materials can be cut and engraved?

With the Rayjet you can laser engrave or cut many different materials: Glass, wood (e.g. MDF), plastics, leather, metal, paper, foam, textiles, etc. For more applications click the button below.

The Rayjet is the ideal laser for use in FabLabs, schools and universities. Typical applications include model making, rapid prototyping, cardboard prototype production, engineering and textile design.

With the Rayjet you can laser engrave or cut many different materials: Glass, wood (e.g. MDF), plastics, leather, metal, paper, foam, textiles, etc. For more applications click the button below.

With the Rayjet the preparation of samples and prototypes (rapid prototyping) is possible within minutes. Even simple designs and sketches can be cut with the laser in order to obtain an initial impression of the final workpiece. Want to learn more about prototyping with the Rayjet? Please contact us.

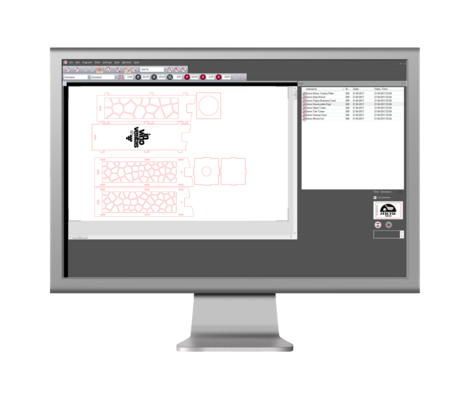

The Rayjet works just like an office printer. Send your text or graphic file directly from your usual graphics program to the laser. As soon as you have selected the type of material, you can start the laser engraving process. In this way even untrained user can use the Rayjet to laser cut and engrave within minutes.

Laser cutting and marking is an entirely non-contact process, which causes no mechanical wear and tear on the laser device and ensures that the Rayjet has a long operational lifetime. You only need to occasionally clean the Rayjet's focus lens, other than that no maintenance is required.

Do you have any questions regarding the Rayjet laser cutter? Then get in touch with us. We are happy to discuss your requirements with you. If you are interested, we will also prepare a customized quote for you.